PV Panel cleaning Brush WLS-2

Contact Us

Phone/whatsApp

+86181-1576-1000(Ziggy)

Phone/whatsApp

+86181-5152-7178(Vicky)

ziggy@wanlvsunny.com

vicky@wanlvsunny.com

Follow Us

PV Panel cleaning Brush WLS-2

Wuxi Wanlv Intelligent Technology Co., Ltd.

Wuxi Wanlv intelligent Technology Co., Ltd. is located in

the Wuxi Economic Development Zone’s Industrial Park. lt isa technology-based enterprise integrating R&D,productionsales and service of photovoltaic cleaning equipment andcleaning robots:We came into being by combining profession-al mechanical design knowledge with solar panel cleaning

experence.

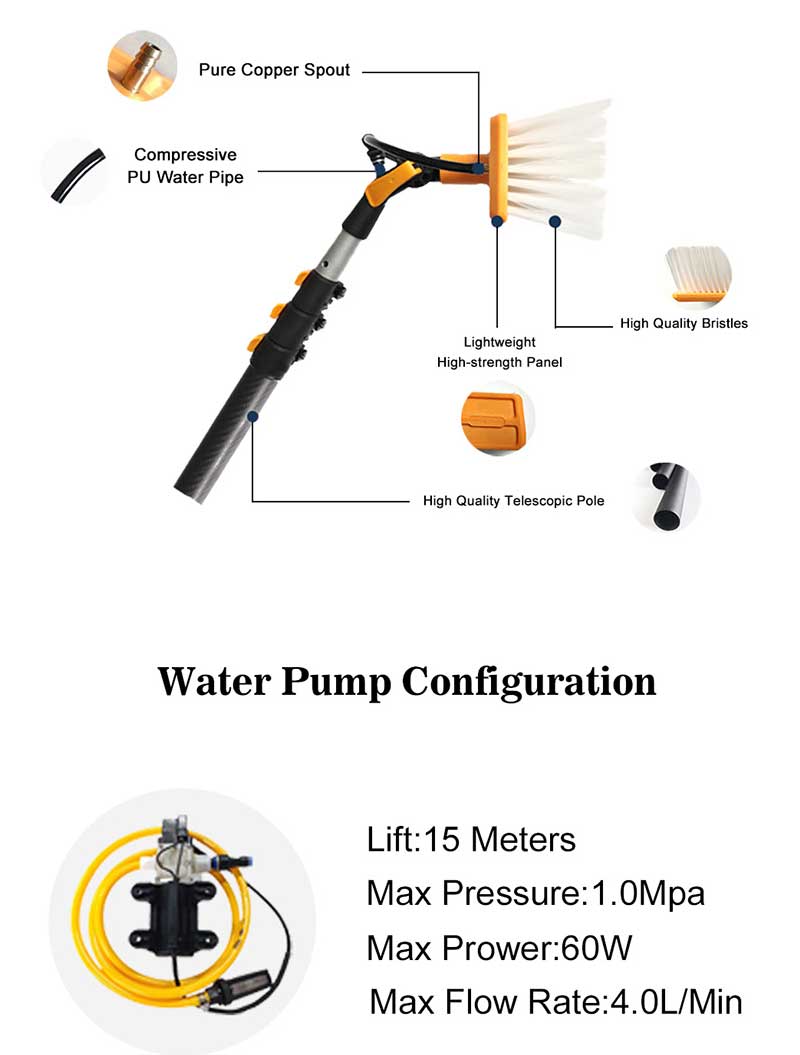

WLS-2 Series Automatic Photovoltaic Cleaning Machine – Product Details

Technical Parameters Standard Version / WLS-2-1

Product Name | Standard Version/WLS-2-1 | |

Water Pipe Material | – | Braided Hose For All Seasons(Anti-winding) |

| Water Pipe Length | Meter | 25-33 |

Water Pipe Outer Diameter | Millimeter | 8 |

| Water Pipe Inner Diameter | Millimeter | 5 |

Water Spray Brush Head Material | – | Nanofiber Stack Materials |

| Brush Head Width | Centimeter | 35 |

Hair Length | Centimeter | 10 |

| Telescopic Pole Material | – | High Strength Aluminum Alloy/Carbon Fiber |

Telescopic Rod Wall Thickness | Millimeter | 1.0 |

| The Telescopic Rod Is The Shortest | Meter | 3.6 |

The Telescopic Rod Is The Longest | Meter | 11.4 |

| Water Supply Method | – | Equipped with a universal connector that can |

Technical Parameters Standard Version / WLS-2-2

| Product Name | Water Pump Version/WLS-2-2 | ||||

| Water Pipe Material | – | Braided Hose For All Seasons(Anti-winding) | |||

| Water Pipe Length | Meter | 25-33 | |||

| Water Pipe Outer Diameter | Millimeter | 8 | |||

| Water Pipe Inner Diameter | Millimeter | 5 | |||

| Water Spray Brush Head Material | – | Nanofiber Stack Materials | |||

| Brush Head Width | Centimeter | 35 | |||

| Hair Length | Centimeter | 10 | |||

| Telescopic Pole Material | – | High Strength Aluminum Alloy/Carbon Fiber | |||

| Telescopic Rod Wall Thickness | Millimeter | 1.0 | |||

| The Telescopic Rod Is The Shortest | Meter | 3.6 | |||

| The Telescopic Rod Is The Longest | Meter | 11.4 | |||

| Water Supply Method | – | Equipped with a universal camera that can be connected to the faucet for water supply; Equipped with a 60W DC water pump to pump water from the bucket for water supply; The water pump pipe is connected to the faucet to achieve secondary pressurization. | |||

Technical Parameters Water Pump Selection

| Product Name | Water Pump Selection | ||||

| Head/Lift | Meter | 15 | |||

| Maximum Pressure | MP3 | 1.0 | |||

| Maximum Power | – | 60W | |||

| Maximum Flow Rate | – | 4.0/MIN | |||

Multi-configuration Options

Product Packaging

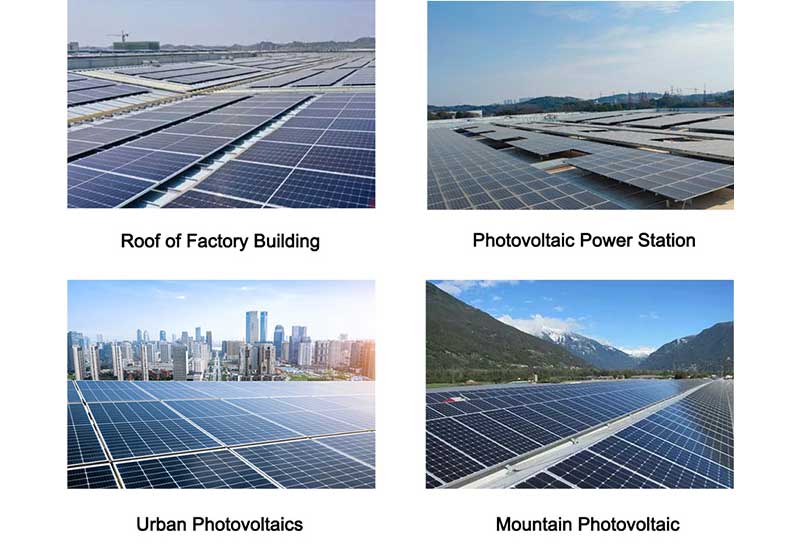

Applicable Scenes

Roof of Factory Building

Urban Photovoltaics

Photovoltaic Power Station

Mountain Photovoltaic

Core Advantages: Redefining PV Cleaning Standards

1. Efficient Dust Removal, Immediate Improvement in Power Generation Efficiency

2. Intelligent Automation, Freeing Up Labor Costs

3. Upgraded Safety Protection, Adapting to Complex Environments

4. Multi-Version Power Supply, Adapting to Full-Scenario Needs

- Mains-Powered Version (WLS-2-1): Powered by 220V mains, equipped with a 16m extended power cord, suitable for rooftop PV or centralized power plants with stable power supply nearby, enabling 24-hour continuous cleaning without frequent charging.

- Lithium Battery Version (WLS-2-2): Powered by a 24V/26Ah large-capacity lithium battery pack, supporting 4-6 hours of continuous operation, and only taking 5 hours to fully charge. Equipped with a portable battery backpack, it is suitable for remote Gobi and desert power plants without mains power, with flexible movement without being restricted by cables.

- Dual-Use Version (WLS-2-3): It has both mains and lithium battery dual power supply modes, which can be flexibly switched according to the on-site power supply situation. It is the best choice for mixed scenarios and emergency cleaning, ensuring uninterrupted cleaning work.

5. Durable Structural Design, Reducing Operation and Maintenance Costs

Applicable Scenarios: Cleaning Solutions for All Types of PV Power Plants

- Large-Scale Ground-Mounted PV Power Plants: Centralized power plants in deserts, Gobi, and plains, adapting to the cleaning needs of ultra-long strings. Automated operation reduces labor transportation and operation costs.

- Rooftop Distributed PV: Scenarios such as enterprise workshops, commercial buildings, and residential rooftops. The lightweight body combined with a flexible telescopic rod can easily cope with complex rooftop environments.

- Remote Power Plants Without Electricity: The lithium battery version does not require mains power and can achieve self-sufficiency when paired with solar charging panels, solving the power supply problem in remote areas.

- High-Dust Pollution Areas: PV projects around mining areas and industrial zones. High-frequency cleaning can effectively resist dust accumulation and maintain stable power generation efficiency.

After-Sales Support: Make Your Investment More Secure

- Authoritative Compliance Guarantee: The product fully complies with the national industry standard GB/T 44264—2024, and has passed multiple safety and performance tests, ensuring reliable quality.

- Comprehensive Warranty Service: Core components (motor, lithium battery, control system) enjoy a 1-year free warranty. During the period, free repair or replacement will be provided for quality problems.

- Customization Support: According to the actual needs of the power plant, parameters such as telescopic rod length, bristle hardness, and power supply mode can be customized to provide exclusive solutions.

- 24-Hour Technical Service: A professional technical team is online around the clock to provide one-stop services such as installation guidance, fault diagnosis, and remote debugging.

- Sample Experience Service: Sample orders are supported, allowing you to test the cleaning effect on-site before bulk purchasing, reducing decision-making risks.

Related products

Contact Information

Phone/whatsApp

+86181-1576-1000(Ziggy)

Phone/whatsApp

+86181-5152-7178(Vicky)

ziggy@wanlvsunny.com

vicky@wanlvsunny.com

Location

Rm507-508, No. 999 Gaolang Road, Binhu District , Wuxi Jiangsu China

Follow Us

Business Hours

Monday – Friday: 9:00 AM – 6:00 PM

Saturday: 10:00 AM – 4:00 PM

Let's Discuss Your Needs

Contact us to learn how our solar panel cleaning solutions can improve your energy output and reduce maintenance costs.