PV Panel Cleaning Robot WLS-7-LM

Contact Us

Phone/whatsApp

+86181-1576-1000(Ziggy)

Phone/whatsApp

+86181-5152-7178(Vicky)

ziggy@wanlvsunny.com

vicky@wanlvsunny.com

Follow Us

PV Panel Cleaning Robot WLS-7-LM

The WLS-7-LM Intelligent Operation & Maintenance Robot is a specialized intelligent cleaning and inspection device developed by Wuxi Wanlv Intelligent Technology Co., LTD, tailored for centralized solar photovoltaic power stations. It integrates dual core functions of PV panel cleaning and intelligent inspection, aiming to enhance power generation efficiency, reduce operation and maintenance costs, and ensure the stable and reliable operation of photovoltaic power stations. With advanced navigation, flexible operation modes, and high-efficiency cleaning capabilities, it becomes a core equipment for intelligent O&M of large-scale PV projects.

Wuxi Wanlv Intelligent Technology Co., Ltd.

Wuxi Wanlv intelligent Technology Co., Ltd. is located in

the Wuxi Economic Development Zone’s Industrial Park. lt isa technology-based enterprise integrating R&D,productionsales and service of photovoltaic cleaning equipment andcleaning robots:We came into being by combining profession-al mechanical design knowledge with solar panel cleaning

experence.

_07.jpg)

_08.jpg)

_02.jpg)

_09.jpg)

_10.jpg)

_11.jpg)

_13.jpg)

_14.jpg)

PV Panel Cleaning Robot WLS-7-LM Core Features

1. Dual Working Modes for Flexible Operation

- Manual Remote Control & Unmanned Driving: The robot supports both manual remote control (for on-demand adjustments) and fully autonomous unmanned driving (for large-scale, continuous operations). This flexibility adapts to diverse site conditions and operational preferences.

- One-Click Operation: Equipped with an integrated remote control terminal, it features one-click start and simplified operation, reducing the learning curve and enabling quick deployment without professional training.

2. High-Efficiency, Dust-Free Cleaning

- Dual-Row Roller Brushes with Vacuum System: Adopts double-row roller brushes rotating in opposite directions, which trap dust in a closed space and directly suction it via built-in dust pipes. This design prevents dust resuspension, achieving thorough one-time cleaning without secondary pollution.

- Professional PV-Friendly Brushes: The roller brushes are made of specialized materials designed exclusively for PV panels. They effectively remove dirt while protecting the panel surface from scratches, ensuring long service life and no damage to components.

- Exceptional Cleaning Efficiency: Boasts a maximum cleaning area of 12,000㎡ per hour (equivalent to 3MW/h), which is 80 times more efficient than manual cleaning. It significantly reduces O&M time and labor input for large-scale PV power stations.

3. Intelligent Perception & Adaptive Performance

- Real-Time Environmental Sensing: Continuously perceives key operational data, including the robot’s pressure on panels, tilt angle, and centering distance. It independently adjusts cleaning postures to adapt to PV panels of different angles and heights, ensuring consistent cleaning quality.

- Strong Terrain Adaptability: Features a four-wheel electric drive chassis with excellent slope-climbing and obstacle-crossing capabilities. It can climb slopes up to 10° and traverse obstacles up to 10cm, handling various terrain conditions in centralized PV stations.

- Wide Adaptive Range: Accommodates PV panels with a ground-to-lower-edge height of 0.1-1.4 meters and a tilt angle of 25°-41°, making it suitable for most standard PV installation layouts.

4. High-Precision Intelligent Inspection

- Dual-Camera & AI-Powered Detection: Equipped with high-definition visible light cameras, infrared thermal imagers, and a dedicated computing module. It leverages artificial intelligence to detect surface abnormalities during cleaning, including hot spots, cracks, damage, bird droppings, leaves, and foreign objects.

- Accurate Fault Identification: The visible light camera detects defects as small as 10mm×10mm, while the infrared camera identifies issues down to 30mm×30mm, ensuring no potential problems are missed.

- Automated Report Generation: Intelligently compiles inspection data into detailed reports, categorizing issues and recording key information (e.g., location, time, and severity). This enables efficient troubleshooting and data-driven O&M decisions.

5. Centimeter-Level Navigation & Positioning

- GNSS + IMU Integrated System: Adopts an advanced arm-type detachable structure with a high-precision GNSS and IMU integrated navigation system. It achieves centimeter-level positioning accuracy, enabling fully autonomous cleaning and inspection without manual intervention.

- Cross-Row Operation Capability: Supports cross-row scheduling and auxiliary cross-row modes, seamlessly navigating between PV panel rows to ensure comprehensive coverage of the entire power station.

6. Visualized Intelligent Network Management

- Dual-Network Communication: Integrates private and public networks to maintain stable information transmission between the robot and the background management platform. It ensures real-time data flow even in remote or complex environments.

- Multi-Terminal Supervision: The JH-2 intelligent O&M platform allows monitoring and control via PC and mobile devices. Users can view real-time status (chassis, roller brushes, vacuum cleaner), video feeds, and autonomous driving data, enabling centralized management of multiple robots (with support for up to 4+ units).

Standard & Optional Accessories

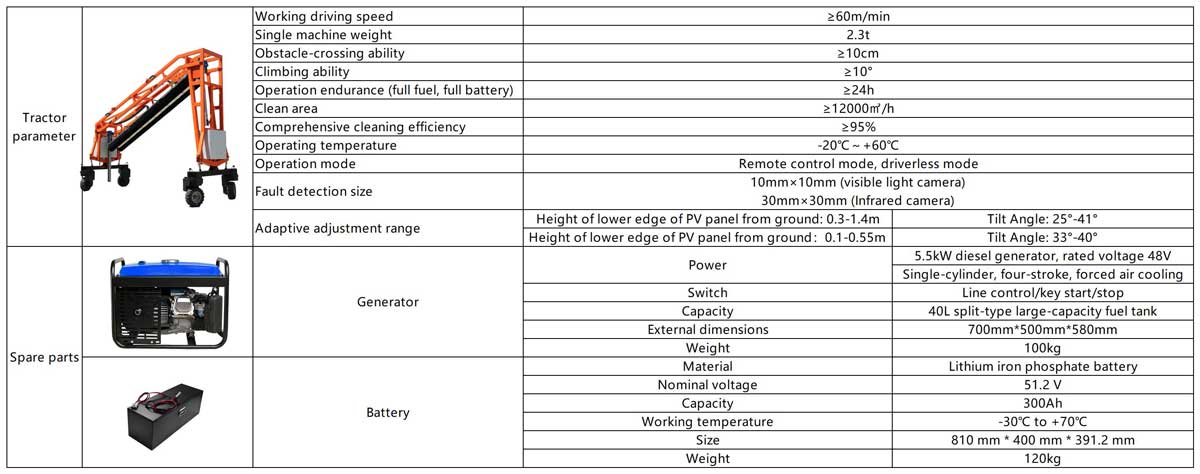

Standard Accessory: Lithium Iron Phosphate Battery

- Nominal voltage: 51.2V

- Capacity: 300Ah

- Operating temperature: -30℃ to +70℃

- Dimensions: 810mm×400mm×391.2mm

- Weight: 120kg

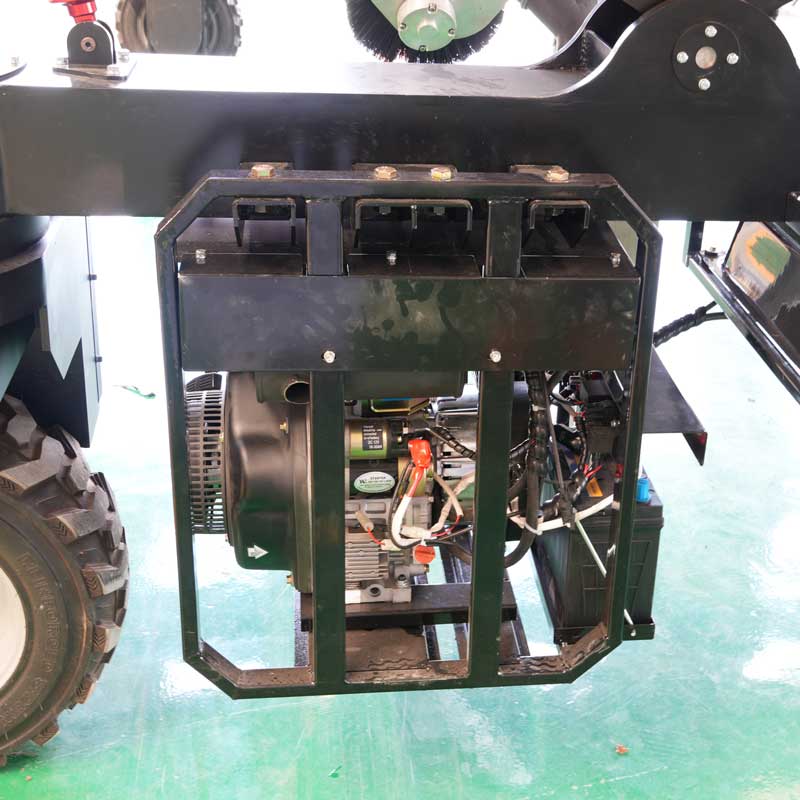

Optional Accessory: Diesel Generator

- Power: 5.5kW

- Rated voltage: 48V

- Type: Single-cylinder, four-stroke, forced air cooling

- Start/Stop Mode: Line control/key operation

- Fuel Tank: 40L split-type large-capacity tank

- External dimensions: 700mm×500mm×580mm

- Weight: 100kg

Cost & Efficiency Advantages

| Indicator | WLS-7-LM Robot | Manual Cleaning |

|---|---|---|

| Cleaning Efficiency | 12,000㎡/h (≈3MW/h) | ≈150㎡/h |

| Efficiency Multiple | 80 times higher than manual | – |

| Cleaning Cost | Approximately 100 yuan/MW | Approximately 2,000 yuan/MW |

| Cost Advantage | 1/20 of manual labor cost | – |

Customization Services

- 5097mm×3800mm×2580mm

- 6097mm×4800mm×2580mm

Application Scenarios

- Large-scale centralized ground-mounted photovoltaic power stations

- Industrial and commercial rooftop distributed PV projects (with suitable access)

- PV facilities in remote areas with high manual O&M costs

- Power stations with complex terrain or challenging panel layouts

- Projects requiring regular inspection and high cleaning frequency

After-Sales Support

- Technical Consultation: 24-hour online support for operation guidance, troubleshooting, and platform usage.

- Maintenance Services: Provide professional maintenance training and on-site support to ensure long-term reliable operation.

- Replacement Parts: Supply genuine replacement parts (e.g., brushes, sensors, batteries) for timely repairs.

- Platform Updates: Continuous upgrades to the JH-2 intelligent O&M platform, adding new features and optimizing performance.

Related products

Contact Information

Phone/whatsApp

+86181-1576-1000(Ziggy)

Phone/whatsApp

+86181-5152-7178(Vicky)

ziggy@wanlvsunny.com

vicky@wanlvsunny.com

Location

Rm507-508, No. 999 Gaolang Road, Binhu District , Wuxi Jiangsu China

Follow Us

Business Hours

Monday – Friday: 9:00 AM – 6:00 PM

Saturday: 10:00 AM – 4:00 PM

Let's Discuss Your Needs

Contact us to learn how our solar panel cleaning solutions can improve your energy output and reduce maintenance costs.