Solar Panel Cleaning Robot WLS-7

Contact Us

Phone/whatsApp

+86181-1576-1000(Ziggy)

Phone/whatsApp

+86181-5152-7178(Vicky)

ziggy@wanlvsunny.com

vicky@wanlvsunny.com

Follow Us

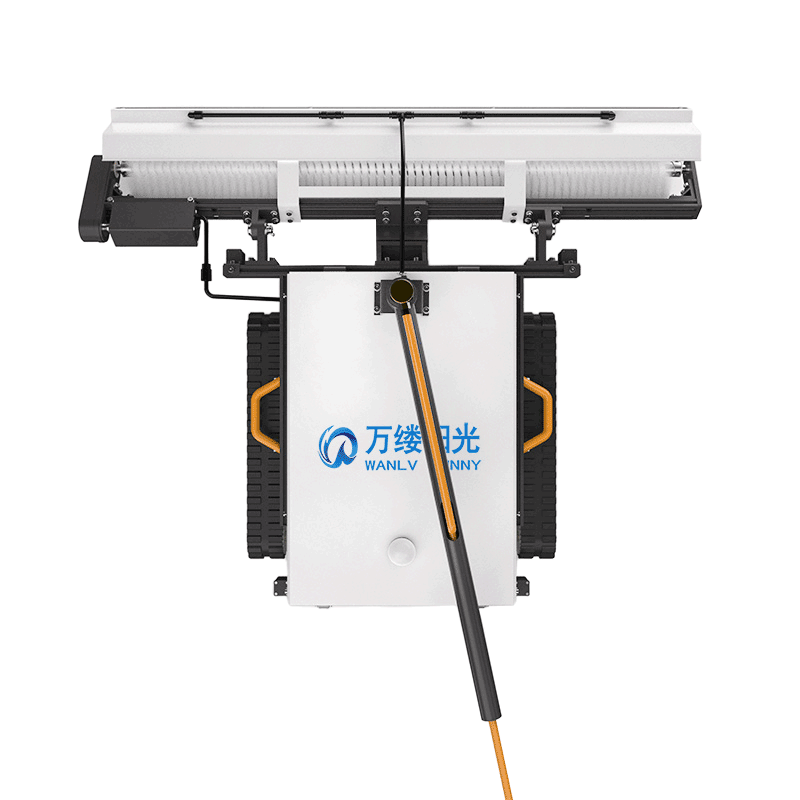

Solar Panel Cleaning Robot WLS-7

The WLS-7 Remote Control Track Solar Cleaning Machine is a professional photovoltaic panel maintenance device engineered to tackle challenging cleaning scenarios where manual access or telescopic pole operation is impractical. Specifically designed for the unique environments of photovoltaic power stations, this robot enables remote-controlled cleaning, eliminating the need for operators to stand on panels or reach inaccessible areas. Equipped with an all-terrain track chassis, dual-mode cleaning capabilities, and comprehensive safety features, it delivers efficient, thorough, and safe cleaning for large-scale PV arrays, rooftop projects, and hard-to-reach panel installations.

Wuxi Wanlv Intelligent Technology Co., Ltd.

Wuxi Wanlv intelligent Technology Co., Ltd. is located in

the Wuxi Economic Development Zone’s Industrial Park. lt isa technology-based enterprise integrating R&D,productionsales and service of photovoltaic cleaning equipment andcleaning robots:We came into being by combining profession-al mechanical design knowledge with solar panel cleaning

experence.

WLS-7 Remote Control Track PV Cleaning Machine

Technical Specifications

| Parameter | Details |

|---|---|

| Working Principle | DC Motor Controls Travel and Brush Rotation |

| Operating Voltage | 24V |

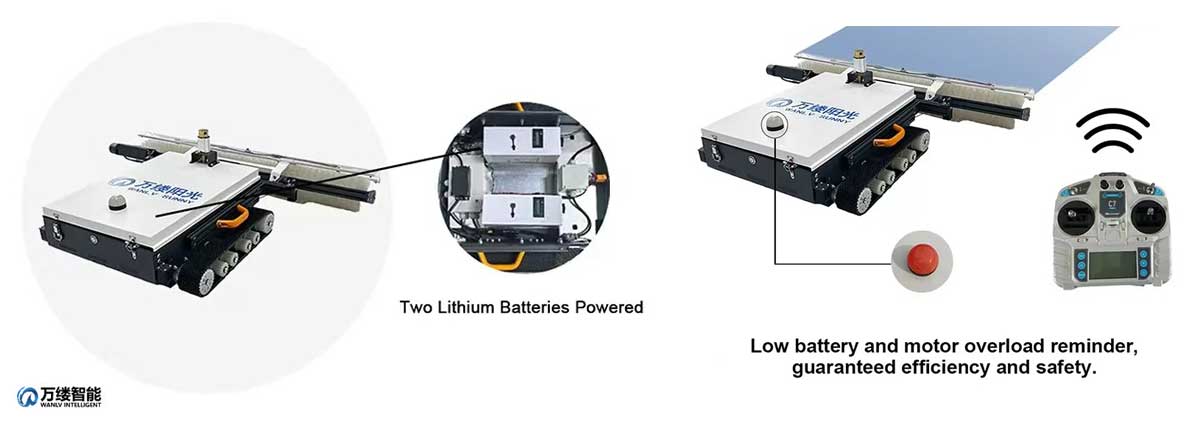

| Power Supply | Lithium Battery (24V)*2 PCs |

| Battery Life | 3-4 hours |

| Idling Speed | 500 Rpm |

| Cleaning Width | 1100 mm |

| Cleaning Type | Dry Cleaning/Washing |

| Bristles Material | Nylon |

| Travel Speed | 11-12 M/min |

| Amount of Water Used | According to the Method of On-site Water Supply |

| Control Method | Remote Handle Control |

| Working Angle | ≤20° |

| Range of Working Temperature | -20-50℃ |

| Dimensions | 1190*970*350mm |

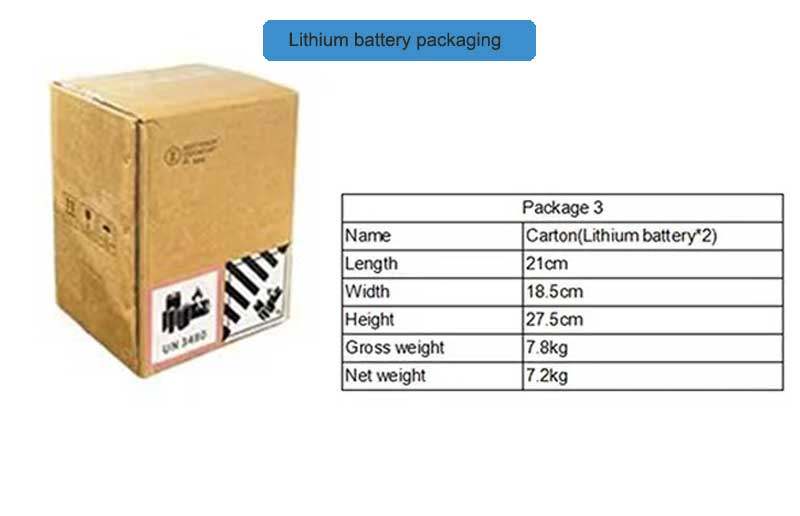

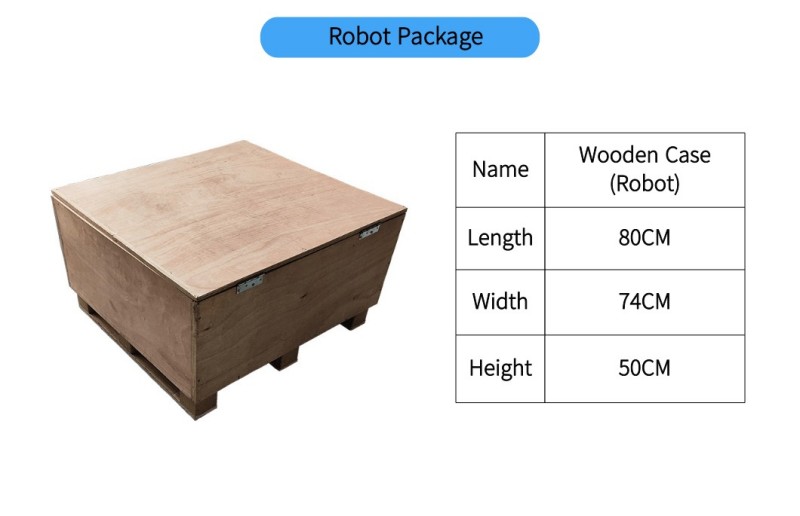

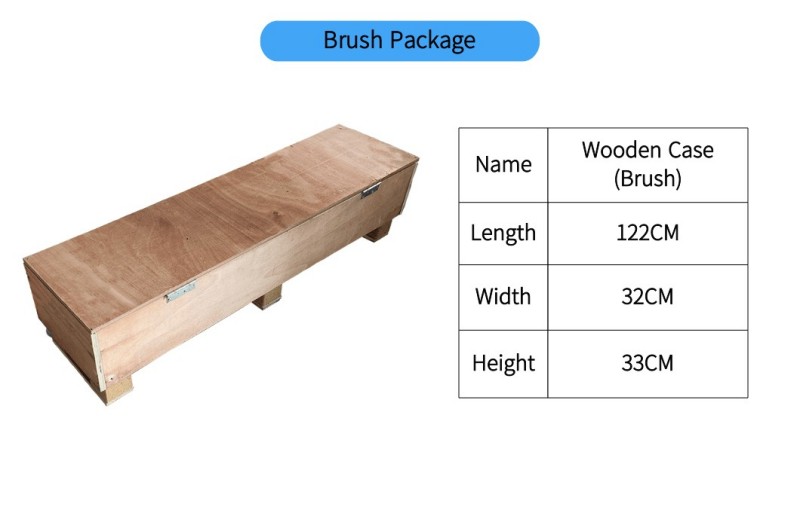

Product Packaging

Application Scenarios

Core Features

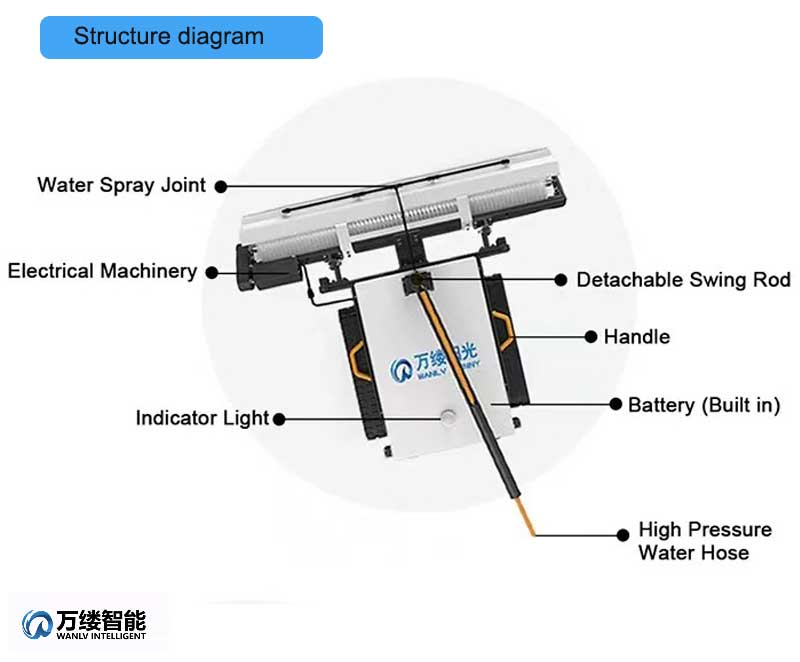

1. All-Terrain Track Chassis for Versatile Movement

- Omnidirectional Mobility: The track chassis allows the robot to move freely in any direction on photovoltaic panels, adapting to various panel layouts and overcoming minor obstacles. It operates seamlessly on inclined surfaces (up to 20° working angle), ensuring no area is left uncleaned.

- Stable & Reliable Traction: The track design provides strong grip, preventing slippage even on smooth panel surfaces, while minimizing pressure on PV modules to avoid damage.

2. Dual-Cleaning Modes & High Efficiency

- Dry/Wet Cleaning Flexibility: Supports both dry cleaning (for light dust and debris) and wet cleaning (for stubborn contaminants). The front-end nozzles deliver targeted water spray during wet cleaning, enhancing cleaning effectiveness without wasting water.

- Impressive Cleaning Performance: Features a 1100mm wide cleaning roller brush, covering large areas per pass. With a travel speed of 22m/min and an idling speed of 250 rpm, it significantly reduces cleaning time for large-scale PV power stations, boosting maintenance efficiency.

- Nylon Bristles for Gentle Protection: The brush head uses high-quality nylon bristles that effectively remove dirt while being gentle on PV panel coatings, avoiding scratches or damage to sensitive surfaces.

3. Remote Control Operation & Safety Assurance

- Long-Distance Remote Control: Comes with a remote control with a 150m operating range, allowing operators to control the robot from a safe distance. This eliminates the risk of falls or injuries associated with manual cleaning on high or inclined panels.

- All-Round Anti-Drop Protection: Equipped with full-range anti-drop sensors. When the robot approaches the edge of the panel (forward/backward), the ultrasonic sensor is triggered, and the warning light flashes rapidly (about 5 times per second) to alert the operator. Normal operation resumes after 3 seconds, preventing accidental falls.

- Sensor Active Shielding: The sensor system includes an active shielding function to avoid false triggers in complex environments, ensuring stable and uninterrupted cleaning.

- Span Spacing Capability: Designed to handle span gaps between panels, adapting to the typical layout of photovoltaic power stations and ensuring continuous cleaning across the entire array.

4. User-Friendly Design & Easy Installation

- Simple Setup Process: Installation takes just four steps—install the lithium battery, connect the water pipe to the water supply joint, place the device on the PV panel, and operate via the remote control. No complex tools or professional training are required.

- Clear Indicator Function: The built-in warning light provides visual feedback for sensor triggers and device status, enabling operators to monitor operations easily.

- Practical Storage Requirements: To prevent bristle deformation, the device should be stored in an upright position with the brush head suspended. Both the robot and battery require a dry, well-ventilated storage environment. For battery maintenance, fully charged batteries should be recharged every 2 months to avoid power loss and damage.

Warranty Information

Warranty Period

- Drive motor, lithium battery, charger: 12 months

- Electronic components: 6 months

Non-Warranty Items & Conditions

- Consumable items (brush heads, tracks, belts, etc.) are not covered by the warranty.

- Damage caused by unauthorized maintenance, misuse, collision, neglect, abuse, liquid intrusion, accidents, modifications, or incorrect use of the product and accessories.

- Malfunctions or damage resulting from human factors.

- Damage caused by force majeure (e.g., natural disasters, extreme weather).

Application Scenarios

- Large-scale ground-mounted photovoltaic power stations with inaccessible areas

- Rooftop distributed PV projects (commercial and industrial buildings)

- PV arrays with steep inclines (up to 20°) where manual cleaning is risky

- Photovoltaic power stations with complex panel layouts or span gaps

- Environments where operators cannot stand safely or telescopic poles cannot reach

After-Sales Support

- 24-Hour Technical Consultation: Provide timely online support for product operation, troubleshooting, and maintenance inquiries.

- Genuine Replacement Parts: Offer high-quality replacement parts for consumables (brush heads, tracks, belts) and core components to ensure long-term use.

- Customization Services: Support tailored solutions for specific power station needs (e.g., extended remote control range, specialized water supply systems).

- Global Shipping & Logistics: Provide reliable shipping options to deliver products to international markets, with flexible trade terms (EXW, FOB, CIF, DAP, DDP).

Related products

Contact Information

Phone/whatsApp

+86181-1576-1000(Ziggy)

Phone/whatsApp

+86181-5152-7178(Vicky)

ziggy@wanlvsunny.com

vicky@wanlvsunny.com

Location

Rm507-508, No. 999 Gaolang Road, Binhu District , Wuxi Jiangsu China

Follow Us

Business Hours

Monday – Friday: 9:00 AM – 6:00 PM

Saturday: 10:00 AM – 4:00 PM

Let's Discuss Your Needs

Contact us to learn how our solar panel cleaning solutions can improve your energy output and reduce maintenance costs.